LY9TC

LY9TC

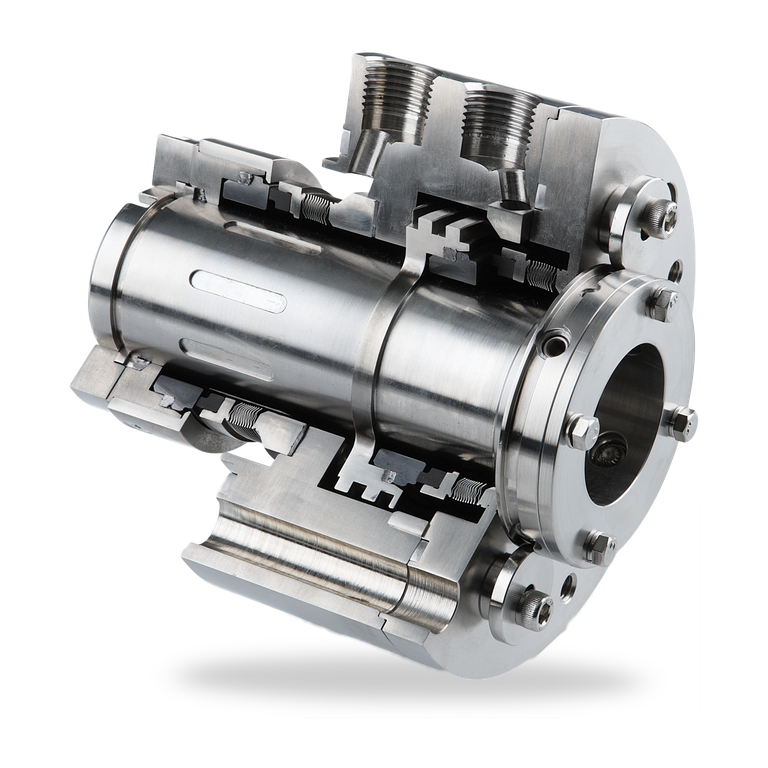

| Item | Description |

| 1.1 | Seal ring with bellows unit |

| 1.2, 11 | Gasket |

| 1.3 | Baffle sleeve |

| 1.4, 7, 24 | Spring washer |

| 1.5, 8, 17,27 | HSH Cap screw |

| 2 | Mating ring |

| 3, 6, 9 | Graphite ring |

| 4 | Retainer |

| 5 | Pin |

| 10 | Seal sleeve |

| 12 | Gland plate |

| 13 | Flow distributor |

| 14 | Retaining ring |

| 15 | Throttle bushing |

| 16 | Adapter |

| 18 | Thrust ring |

| 19 | Drive ring |

| 20 | Split ring |

| 21 | Drive collar |

| 22 | Clamp sleeve |

| 23 | Set screw |

| 25 | Hexagon bolt |

| 26 | Setting device |

F Flush

Q Quench

D Drain

LY9TC

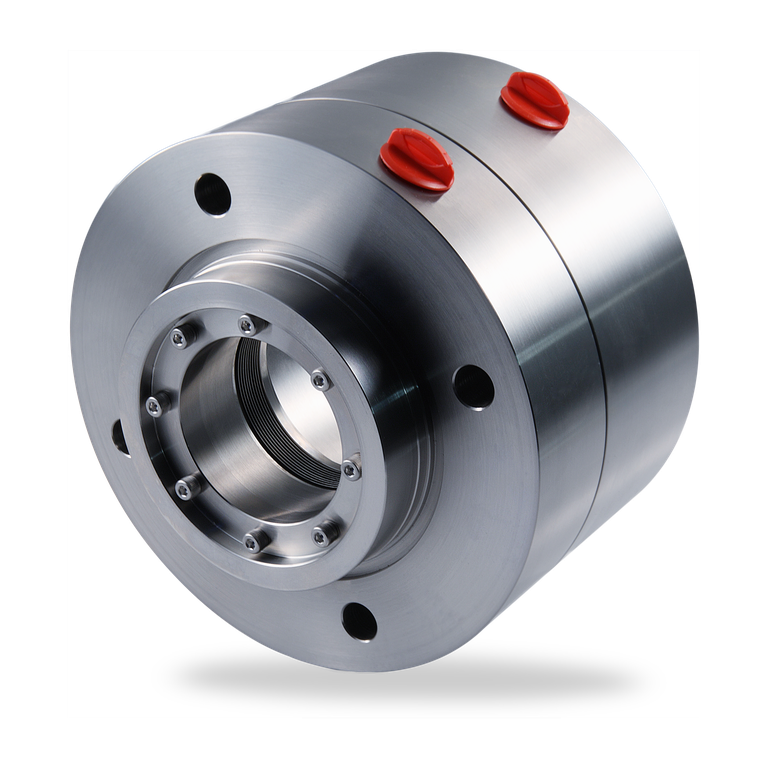

Features

- API 682 Category 2 and 3, Type C, Arrangement 1 seal

- Single seal

- Balanced

- Cartridge unit

- Stationary metal bellows

- Shrink fitted seal ring and solid mating ring

Advantages

- Suitable for higher speeds

- Good followability due to no influence from run-out, squareness or vibration of the shaft

- Compact design

- Low heat generation and power consumption due to narrow seal face width

- Longer seal life

- Also available in double ply design

- Suited for applications with extreme high and low temperatures

- Absence of dynamic O-Ring eleminates/reduces seal face hang-up

- Bellows design minimizes variation in face load due to shaft expansion or face wear

- Resistant to abrasive particles in the medium, no shaft or sleeve fretting

Materials

Seal ring: Blister resistant carbon,

Silicon carbide SSiC (Q1), RBSiC (Q2)

Mating ring:

Silicon carbide SSiC (Q1), RBSiC (Q2)

Bellows: Inconel® 718 (M6)

Secondary seals: Graphite (G)

Metal parts: CrNiMo steel 316 (G),

Carpenter® 42 (T4)

Silicon carbide SSiC (Q1), RBSiC (Q2)

Mating ring:

Silicon carbide SSiC (Q1), RBSiC (Q2)

Bellows: Inconel® 718 (M6)

Secondary seals: Graphite (G)

Metal parts: CrNiMo steel 316 (G),

Carpenter® 42 (T4)

Standards and approvals

- API 682 / ISO 21049

- API 682 4th ed. Cat. 2/3 - 1CW-FL

Recommended applications

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- LPG plants

- API 610 / ISO 13709 pumps

- Process pumps

Recommended piping plans

Similar products

LY9DSTT

- API 682 Category 2 and 3, Type C, Arrangement 3 seal

- Dual seal in face-to-face arrangement

- Balanced

- Cartridge unit

- Stationary metal bellows

- Shrink fitted seal rings and solid mating rings

LY9DZTT

- API 682 Category 2 and 3, Type C, Arrangement 2 and 3 seal

- Dual seal in face-to-back arrangement

- Balanced

- Cartridge unit

- Stationary metal bellows

- Shrink fitted seal rings and solid mating rings

MBS100

- For unstepped shafts

- Rotating bellows

- Single Seal

- Balanced

- Independent of direction of rotation