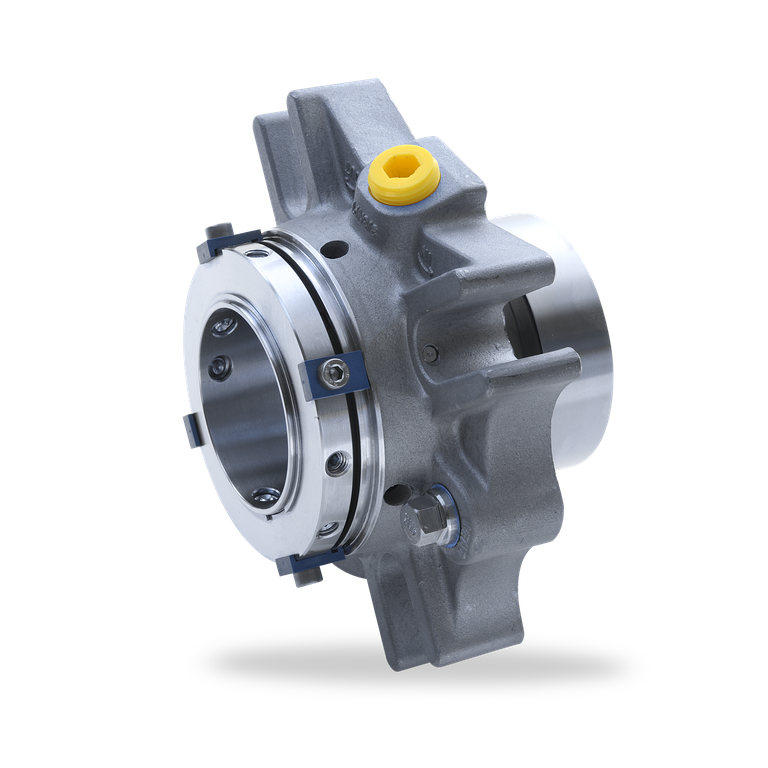

eCartex ANSI

Dual seals

eCartex ANSI

Dual seals

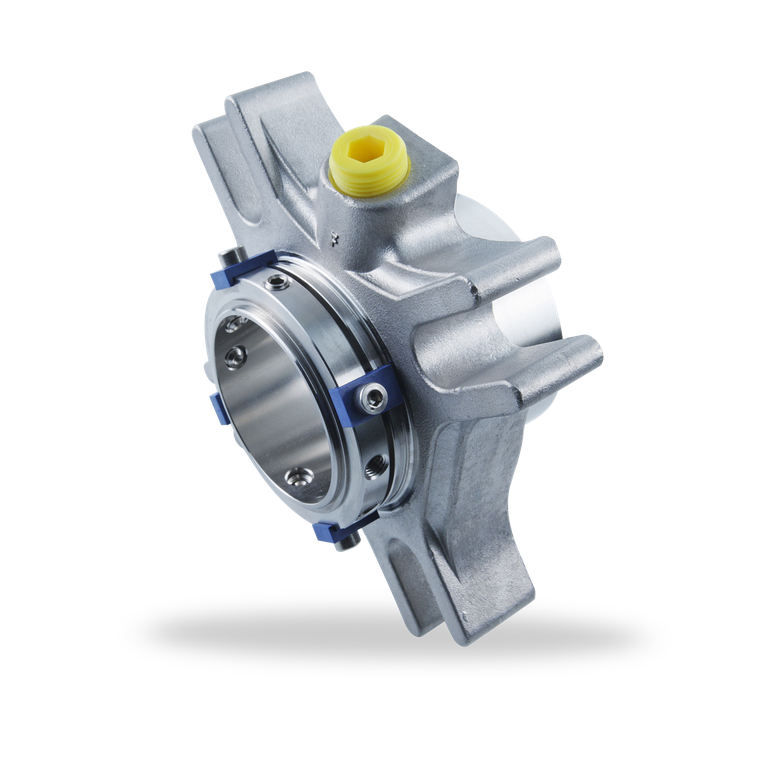

| Item | Description |

| 1 | Seal face |

| 2, 5, 7, 10, 13, 15 | O-Ring |

| 3 | Spring |

| 4 | Seat |

| 6 | Shaft sleeve |

| 8 | Cover |

| 9 | Seal face |

| 11 | Spring |

| 12 | Seat |

| 14 | Drive collar |

| 16 | Set screw |

| 17 | Snap ring |

| 18 | Assembly fixture |

| 19 | Hex socket head screw |

| 20 | Gasket |

| 21 | Screw plug |

| 22 | Gasket |

eCartex ANSI

Dual seals

Features

- Dual seal

- Available for standard (eCartex-ASDN) and big bore (eCartex-ABDN) seal chambers

- Cartridge

- Balanced

- Independent of direction of rotation

- Double pressure balanced

- Integrated pumping device

Advantages

- The series has sliding surfaces that are equipped with EagleBurgmann DiamondFace technology as standard

- Up to 80 % less energy consumption and minimized heat generation of seal due to friction-reducing DiamondFace layer

- Up to 100 % extended operating period, prolongation of MTBF and MTBR intervals

- Significantly improved dry-run capability for inadequately lubricated sealing surfaces, thus vastly improved process safety

- Universally applicable, even with high solids content in the medium

Materials

Seal face product side: Silicon carbide DiamondFace® (Q15)

Seat product side: Silicon carbide DiamondFace® (Q15)

Seal face atmospheric side: Carbon graphite resin impregnated (B)

Seat atmospheric side: Silicon carbide (Q1)

Secondary seals: FKM (V), EPDM (E), FFKM (K), Perfluorcarbon rubber/PTFE (U1)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), CrNiMo cast steel (G)

Seat product side: Silicon carbide DiamondFace® (Q15)

Seal face atmospheric side: Carbon graphite resin impregnated (B)

Seat atmospheric side: Silicon carbide (Q1)

Secondary seals: FKM (V), EPDM (E), FFKM (K), Perfluorcarbon rubber/PTFE (U1)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), CrNiMo cast steel (G)

Standards and approvals

- ANSI

Recommended applications

- Process industry

- Petrochemical industry

- Chemical industry

- Pharmaceutical industry

- Power plant technology

- Pulp and paper industry

- Water and waste water technology

- Mining industry

- Food and beverage industry

- CCUS

- Universally applicable

- ANSI process pumps

Similar products

Cartex Dual seals

- Dual seal

- Cartridge

- Balanced

- Independent of direction of rotation

- Double pressure balanced

- Integrated pumping device

- Variants available: for eccentric screw pumps (-Vario) and gas-lubricated version (-GSDN)

Cartex Single seals

- Single seal

- Cartridge

- Balanced

- Independent of direction of rotation

- Single seals without connections (-SNO), with flush (-SN) and with quench combined with lip seal (-QN) or throttle ring (-TN)

- Additional variants available for ANSI pumps (e.g. -ABPN) and eccentric screw pumps (-Vario)

Cartex ANSI Single seals

- Single seal

- Available for standard (Cartex-ASPN) and big bore (Cartex-ABPN) seal chambers

- Cartridge

- Balanced

- Independent of direction of rotation

- Single seals with flush (-ASPN, -ABPN) and with quench combined with lip seal (-ASQN, -ABQN) or throttle ring (-ASTN, -ABTN)