TSB6

Barrier/buffer fluid system

TSB6

Barrier/buffer fluid system

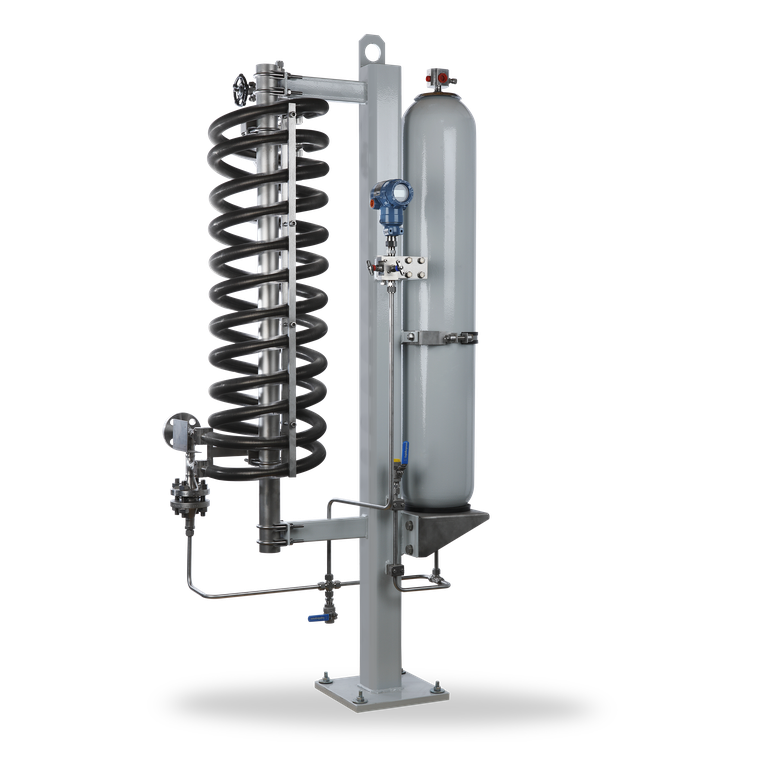

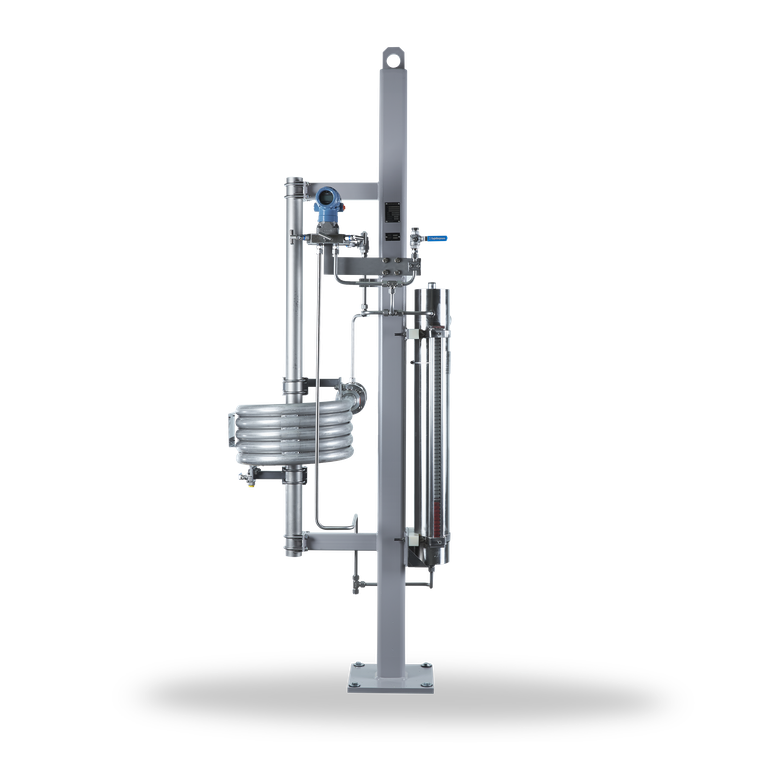

TSB6000A4 for API Plan 52, API Plan 53A

A From mechanical seal

B To mechanical seal

C Filling connection

D Cooling water IN

E Cooling water OUT

F Drain

G Connection to flare

A From mechanical seal

B To mechanical seal

C Filling connection

D Cooling water IN

E Cooling water OUT

F Drain

G Connection to flare

TSB6

Barrier/buffer fluid system

Features

The EagleBurgmann barrier/buffer fluid systems of the TSB6000A4 range meet all the requirements to supply mechanical seals in accordance with the API682 4th edition guidelines. The vessels are equipped with all essential connections for fitting additional components.

TSB6 bottom-flanged vessels are available in two standard sizes. A version with dished heads (TSA6000A4) is also available.

The modular system allows the TSB6000A4 vessels to be combined with a wide range of system components, such as level transmitter, pressure transmitter, base frame, etc.

TSB6 bottom-flanged vessels are available in two standard sizes. A version with dished heads (TSA6000A4) is also available.

The modular system allows the TSB6000A4 vessels to be combined with a wide range of system components, such as level transmitter, pressure transmitter, base frame, etc.

Advantages

- Operating limits up to 44 bar / 260 °C

(638 PSI / 500 °F): suitable for a wide range of demanding operating conditions - Robust design with weld-pad type sightglass for optimum visual level monitoring

- Modular system: combination possible with a wide range of system components

Standards and approvals

- API 682 / ISO 21049

- API 682 4th ed. Cat. 2/3 - 2CW-CW

- API 682 4th ed. Cat. 2/3 - 3CW-FB

- API 682 4th ed. Cat. 2/3 - 3CW-BB

- API 682 4th ed. Cat. 2/3 - 3CW-FF

- API 682 4th ed. Cat. 1 - 2CW-CW

- API 682 4th ed. Cat. 1 - 3CW-FB

Recommended applications

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

Functional description

The TS system performs all the basic functions of a barrier/buffer system for the operation of dual seals:

- To pressurize the barrier/buffer chamber

- Leakage compensation

- Barrier/buffer fluid is circulated by thermosiphon effect or forced circulation system

- To cool the seal

- To selectively absorb product leakage and prevent dry running (tandem arrangement)

Use compressed air or nitrogen for pressurization; pressurization is monitored by a pressure transmitter (default). The incorporated level transmitter issues a signal whenever the level of barrier/buffer fluid is too low.

- To pressurize the barrier/buffer chamber

- Leakage compensation

- Barrier/buffer fluid is circulated by thermosiphon effect or forced circulation system

- To cool the seal

- To selectively absorb product leakage and prevent dry running (tandem arrangement)

Use compressed air or nitrogen for pressurization; pressurization is monitored by a pressure transmitter (default). The incorporated level transmitter issues a signal whenever the level of barrier/buffer fluid is too low.

Notes

Design and production in accordance with EU Pressure Equipment Directive PED 2014/68/EU available.

Design, calculation and production acc. to ASME VIII, Div. 1 available.

3rd party inspection, ASME stamp on request.

Design, calculation and production acc. to ASME VIII, Div. 1 available.

3rd party inspection, ASME stamp on request.

Recommended piping plans

Product variants

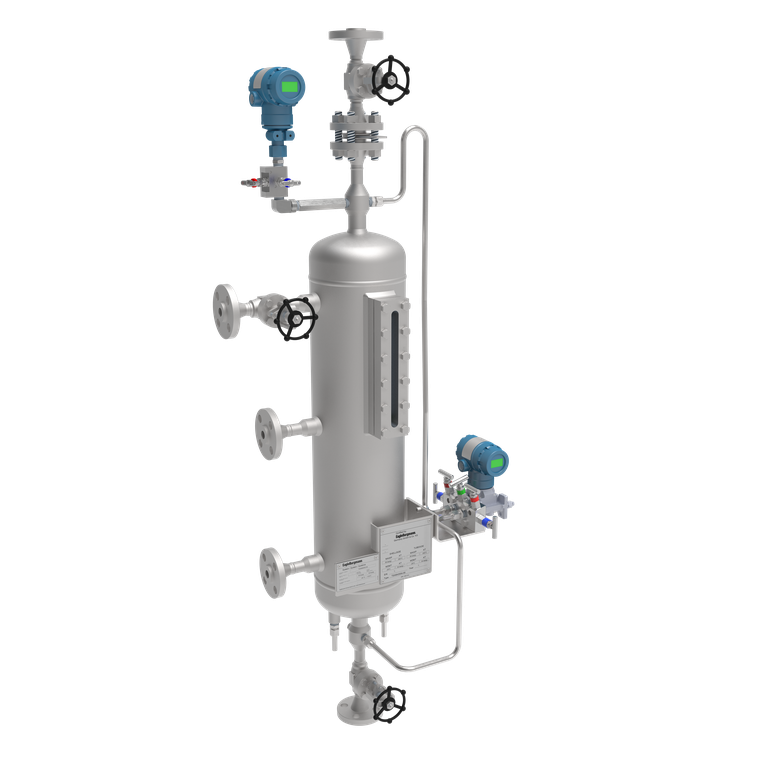

TSB6000A4 for API API Plan 53A

| Designation | TSB6000A4 | TSB6001A4 | TSB6002A4 | TSB6003A4 |

|---|---|---|---|---|

| Design code | ASME VIII, Div. 1 w/o U-stamp |

PED 2014/68/EU | ASME VIII, Div. 1 w/o U-stamp |

PED 2014/68/EU |

| For shaft diameters ≤60 mm (acc. to API 682) |

■ | ■ | ||

| For shaft diameters >60 mm (acc. to API 682) |

■ | ■ | ||

| Integrated cooling coil | ■ | ■ | ■ | ■ |

| Volume – vessel (liters) | 15 | 15 | 26 | 26 |

| Volume – tube (liters) | 0.3 | 0.3 | 0.4 | 0.4 |

| Allowable pressure – shell1) | 44 bar (638 PSI) | 44 bar (638 PSI) | 44 bar (638 PSI) | 44 bar (638 PSI) |

| Allowable pressure – tube1) | 44 bar (638 PSI) | 44 bar (638 PSI) | 44 bar (638 PSI) | 44 bar (638 PSI) |

| Allowable temperature – vessel1) | -29 °C … +260 °C (-20 °F … +500 °F) |

-29 °C … +260 °C (-20 °F … +500 °F) |

-29 °C … +260 °C (-20 °F … +500 °F) |

-29 °C … +260 °C (-20 °F … +500 °F) |

| Allowable temperature – system1) | -29 °C … +260 °C (-20 °F … +500 °F) |

-29 °C … +260 °C (-20 °F … +500 °F) |

-29 °C … +260 °C (-20 °F … +500 °F) |

-29 °C … +260 °C (-20 °F … +500 °F) |

| Liquid volume at NLL – Normal Liquid Level (liters) |

12 | 12 | 20 | 20 |

| Working volume MAX-MIN (liters) | 4 | 4 | 6.5 | 6.5 |

| Cooling capacity – without cooling water (kW)2) |

0.75 | 0.75 | 1 | 1 |

| Cooling capacity – natural circulation (kW)2) |

1.9 | 1.9 | 2.5 | 2.5 |

| Cooling capacity – forced circulation (kW)2) |

5.0 | 5.0 | 6.5 | 6.5 |

| Metal parts | 316/316L | 316/316L | 316/316L | 316/316L |

| Sight-glass | Borosilicate | Borosilicate | Borosilicate | Borosilicate |

| Gaskets | PTFE | PTFE | PTFE | PTFE |

Other versions and connections (flanged, threaded, welded) on request.

1) Design data, permissible working values depend on the actual conditions of service.

2) The cooling performance depends on the available fluids, their temperatures and flow rates. Please contact EagleBurgmann for professionally selecting the correct heat exchanger.

Similar products

SPB6 Barrier fluid system with bladder accumulator

Pressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes. The SPB6000A4 (Plan 53B) range is available with a pressure accumulator, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

A refilling unit has to be provided.

A refilling unit has to be provided.

SPC6 Barrier fluid system with piston accumulator

Pressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes.

The SPC6000A4 (API Plan 53C) range is available with a pressure booster, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

A refilling unit must be provided.

The SPC6000A4 (API Plan 53C) range is available with a pressure booster, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

A refilling unit must be provided.

TSA6 Barrier/buffer fluid system

The EagleBurgmann barrier/buffer fluid systems of the TSA6 range meet all the requirements to supply mechanical seals in accordance with the API682 4th edition guidelines. The vessels are equipped with all essential connections for fitting additional components.

Available as bottom flanged version (TSB6) which can be dismantled for optimized and easy cleaning purpose of the inside of the vessel.

The modular system allows the TSA6/TSB6 vessels to be combined with a wide range of system components such as level transmitter, pressure transmitter, base frame, etc.

Available as bottom flanged version (TSB6) which can be dismantled for optimized and easy cleaning purpose of the inside of the vessel.

The modular system allows the TSA6/TSB6 vessels to be combined with a wide range of system components such as level transmitter, pressure transmitter, base frame, etc.